НОВО: проекти во тек

Хибриден колектор за комбинирано производство на електрична и топлинска енергија

Центарот за плазма технологии ПЛАЗМА доо Скопје, е добитник на грант од фондот за технолошки развој и иновации “ФТИР” преку Инструментот за поддршка - Кофинансирани грантови за подобрување на иновативноста на проектот “Подобрен ФВТ колектор со нов дизајн за истовремено производство на електрична и топлинска енергија вграден во комбиниран соларен систем за греење, ладење и климатизација на резиденцијални и комерцијални корисници”

Крајните корисници, домаќинста, индустијски објекти, хотели, болници, спортски објекти и терени, базени имаат потреба како од топлинска така и од електрична енергија. Многу често , лимитираната површина на крововите и фасадите не дозволува да се добие доволно енергија за покривање на потребите од електрична и топлинска енергија.

ФВТ колeкторот е најдоброто решение за овие цели бидејки од истата површина овозможува добивање како на електрична така и топлинска енергија и тоа:

20% повеќе електрична енергија и 3 пати повеќе топлинска енергија во споредба со стандарден ФВ панел. Калкулациите што ги изработуваме за потребите на крајни корисници кажуваат дека ФВТ колекторот го намалува повратот на инвестицијата и ја зголемува заштедата на енергија за период од експлоатацијата, со што ФВТ претставува навистина една од најдобрите можности за искористување на сончевата енергија за добивање на електрична и топлинска енергија во исто време Клучните ЕУ критериуми за проценка на загадувањето од изворите на енергија се: CO2 емисија/ kWh, загадување на човековата околина со токсични гасови и ПМ честички/kWh, Цена /kWh, инсталиран на кровови и фасади со што се избегнува користењето на обработливо земјиште за добивање на енергија. Предложениот ФВТ интегриран систем, потполно ги исполнува сите овие критерими т.е. е најдобар извор на енергија кој не само што не емитира CO2 и други стакленички гасови туку не емитира и токсични т.н. ПМ честички. Фондот за иновации и технолошки развој ФИТР го препозна и подржа овој преоект а со тоа ни помогна да заедно со нашето учество ја реализираме оваа зацртана цел која ја имавме поставено од пред неколку години но секако немавме доволно средства за да се реализираат сите развојно истражувачки активности , тестирања во овластени инситуции и добивање на највисоки цертификати како и

News - temporary projects

PVT Hybrid Collector for combined production of electrical and thermal energy

Final design of an improved PVT (photovoltaic-thermal) collector for combined heat and power generation, as well as the development of combined solar systems with heat pumps and a new concentrating collector for use in heating systems, cooling and air conditioning of residential and commercial users.

The project will be implemented by Plasma as applicant in cooperation with Pikcell producer of PV panels, Camel Solar producer of absorbers and Solar ET assembling of the PVT, as well as several important external experts and consultants from Europe and the Republic of North Macedonia in the field of development and testing of PVT collector, adhesives, self-cleaning coatings and other business support services.

The key criteria for assessing pollution of the energy sources are: CO2 emissions / kWh, environmental pollution with toxic gases and PM particles / kWh, Price / kWh, as well as minimal use of arable land for energy generation and price/kWh. The proposed PVT integrated system fully meets all these criteria.

Generally, Solar energy is using separately, PV panels for receiving electricity and Solar thermal collectors for receiving hot water.

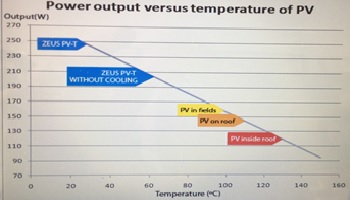

In both options devices are using only one part of solar energy, electricity or heat. The conversion rate of solar radiation into electricity by photovoltaic depends on cell type and it is between 5% - 25%. For PV panels with polycrystal cells is around 13%. The greater part of the absorbed solar radiation by photovoltaic is converted into heat (at about 70% - 80%), increasing cell temperature. This effect reduces their electrical efficiency around (0,5% / 0C). Diagram 1 presents PV efficiency vs. temperature dependence.

In façade or inclined roof installation on buildings the thermal losses are reduced due to the thermal protection of PV rear surface and PV modules operate at higher temperatures. This undesirable effect can be avoided by applying a suitable heat extraction with a fluid circulation, air or liquid (water), keeping the electrical efficiency at a satisfactory level.

Regarding that measurement’s it is very clear that PV efficiency depends from temperature from PV cells.

PVT device give double effect to end user : More electricity /year around 20% (depends from climate of the region) and around three times more thermal energy compare with standard PV panel.

If PV panel is not cooled during the summer, PV panel on roofs or facades will achieve temperature more than 800 C. Keeping temperature to around max 500 C , additional benefit of PV panels is longer tool live of PV . The reason of this very important advantage is lower diffusion coefficient of defects’ to lower temperatures compare with higher temperatures and laminations of EVA to PV panels has limited working tempearure. As results of this phenomena efficiency on higher temperatures and tool life is decreased. Producing energy with maximum efficiency and long term stability is very important and more than necessary now .

Our aim is producing electricity and hot water with nearly zero CO2 emission and pollution, additionally as much as possible minimum requirement from public network.Fund for innovation and technology development FITR, recognize and support our R&D activities, testing, certifications in world famous institutes, marketing and help us to realize the project.

Realized Projects

I. Nasov, Project title: New compact absorber for solar collectors with selective coatings, Co-financed Project by the Ministry of Education and Science of R. Macedonia, 2006.

I. Nasov, project title: Increasing of efficiency coefficient on vacuum tubes collectors using new types of absorbers, Co financed by Ministry of education and science of R. Macedonia 2008.

Project: H2 barrier on Ti plate ( special project for hydrogen energy application ) NDA with Agzo Nobel

Reflective coating on flexibile high transparent Willow glass, NDA with Corning

Combination between PVD coating and organic coating for bariere coatings on biodegradible foil for packaging to improve water and oxygen permeability ,NDA with Fraunkofer institute Wurzburg

Solar thermal collectors integrated in architecture: facades and roofs, co financed from Austrian development agency, 2009.

EURECA project title, SURFACE +, “SYSTEMS FOR ASSESSMENT OF SURFACE INTEGRITY” (SURFACE +) participnts: Gorenje Orodjarna, d.o.o. TECOS Razvojni center orodjarstva Slovenije DESARROLLO INDUSTRIAL EMBELL SL , AITIIP FOUNDATION (Partner), ZARAGOZA, SPAIN, CIRKO Center for research, development and continual education, Center for plasma technologies "PLASMA" doo

EURECA project title , DE_AMATECH, FESTO d.o.o., Ljubljana, Plasma , Institute of Chemistry Slovenija, Faculty of Science ,Faculty of Technology and Metallurgy Slovenija, FESTO d.o.o., Ljubljana Institute of Chemistry, Faculty of Science (task 2, 6 and 7), Faculty of Technology and Metallurgy (task 2, 6 and 7), 11Oktomvri – EUROKOMPOSIT (task 7), Centre for Plasma technologies – Plasma

EUREKA –RD , Polycoat , 2130-13-090005, Development of new materials, tools and technologies for depositing of thin polymer coatings on the EM stator. Skupina Inkom d.o.o.,Plasma doo, Univerza v Ljubljani, Fakulteta za strojništvo, Laboratorij LASIM, Aškerčeva 6, 1000 Ljubljana

ЕУ FP7 POLYSOL project, Development of a modular, all-POLYmer SOLar thermal collector for domestic hot water preparation and space heating, Research for the benefit of SMEs PROJECT NO: 262149 EFFECTIVE DATE: 03 December 2009, GRANT AGREEMENT : FP7- SME-2010-1/262149, RTD performers:

Centar Za Plasma Tehnologii Plazma DOO , Universitaet Stuttgart , The Materials Technology Research Institute Limited , FUNDACION INASMET , Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V.

ЕU FP7 Composol project: Fibre Reinforced Composite Reflectors for Concentrated Solar Power Plants, Research for the benefit of SMEs, Grant Agreement: 284216, RTD Performers:TWI LIMITED TWI -United Kingdom , DEUTSCHES ZENTRUM FUER LUFT UND RAUMFAHRT EV DLR -Germany , CENTAR ZA PLAZMA TEHNOLOGII PLAZMA DOO

EU FP7 Dibiopack project, DEVELOPMENT OF INJECTION AND BLOW EXTRUSION MOLDED BIODEGRADABLE AND MULTIFUNCTIONAL PACKAGES BY NANOTECHNOLOGY- IMPROVEMENT OF STRUCTURAL AND BARRIER PROPERTIES, SMART FEATURES AND SUSTAINABILITY , FP7-NMP-2011-LARGE-5, Grant agreement no: 280676, RTD performers: FUNDACION AITIIP AITIIP Spain, CONSORZIO INTERUNIVERSITARIO NAZIONALE PER LA SCIENZA E TECNOLOGIA DEI MATERIALI INSTM Italy , LABORATORI ARCHA SRL ARCHA Italy , Gorenje Orodjarna, d.o.o., Velenje, Partizanska 12 GORENJE Slovenia , RAZVOJNI CENTER ORODJARSTVA SLOVENIJE TECOS Slovenia, CENTAR ZA PLAZMA TEHNOLOGII PLAZMA DOO PLASMA, AVANZARE INNOVACION TECNOLOGICA SL AVANZARE Spain, INCERPLAST SA INCP Romania , FRAUNHOFER-GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG E.V Fraunhofer ISC Germany

Project: H2 barrier on Ti plate ( special innovative project for hydrogen energy application ) NDA with Agzo Nobel

FP7 EAGLE

FP7 Renew X

FP 7 Soleglass

H2020 Plasstel, plasma nitriding of stainless steel , consultant

Patents

Z. O. Vitalovich, I. Nasov, The way of forming PVD coatings on the surface of the constructive steel after plasma nitriding, 74749, MPK 2006, Ministry of Education and Science, Ukraina, 2006

I. Nasov, Selective coatings on absorbers for solar collectors, P-2006/83,

I. Nasov, Absorbers for solar collectors with selective coatings on the wings and on the tubes of the absorbers P-2007/153

Rewards

Grand Prix - Innovation: PVD, Plasma Nitriding and Oxinitriding, Macedonian Economic Chamber, Technoma–Makinova, Skopje, 2005

Winner in Western Balkans Development Marketplace - Project Title: New compact absorber for solar collectors with selective coatings, Organized by The World Bank, Belgrade, 2006

Gold Medal - Nikola Tesla - Innovation: Plasma oxinitriding, Belgrade Association of Inventors and Technical Improvements, International Fair of Innovation, Belgrade, 2006

I-st Place Diploma - Academy of Innovators of Serbia and API SCG, International Fair of Innovation, Belgrade, 2006 During these 4 years, Plasma researched and developed many new plasma nitriding processes, PVD coatings, new ecological galvanic, chemical and electrochemical coatings and combinations of these technologies. Some of them are patented in the country and abroad:

Current research & development activities:

Antibacterial coatings based on Ag, Cu, Ti...and many the other metals ...

Bariere coatings for water and oxygen permeability’s on polymers and the other metallic or non metallic substrates.

AR coatings for solar energy application, specially for solar absorbers

Reflective coatings : Ag, Al , Stainless steel ...applicated on metals or non metals materials.

Hydrophobic and hydrophilic coatings

Special plasma nitriding process on Stainless steel substrates to increase wear resistant, hardness....with higher corrosion resistant than normal stainless steel without plasma nitriding treated , specially created for food industry equipment.

Recently, the company started to work with combination of the above-mentioned procedures for industrial applications. The newest method in “Plasma”, which is still in development state , is the original plasma duplex process: plasma nitriding + vacuum plasma active screen coating with alloying metals: Cr, Mo, W, Al. + PVD coating . With this method, the microstructure and the properties of the surface layer are improved and the characteristics increase additional.

Consulting of Producing new PVD and plasma nitriding chambers